Description

Features

| 1.The ATC of supporting seat and column are one-piece. It is stability when tool change tool. | ||

| 2.Roller type Linear Guideway and C3 Ball Screw on X,Y,Z- axis | ||

| 3.The base structure is reinforced by internal ribbing to ensure high rigidity and stability. It is suitable for heavy cutting and precision machining | ||

|

|

|

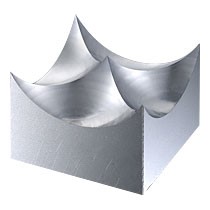

| Total Machining Time: 1hr. 6min. 10sec Workpiece Dimension: 100 x 100 x 50mm Material:NAK-80 No. of tools used: 3 |

Total Machining Time: 27min. 46sec Workpiece Dimension: 100 x 100 x 50mm Material: NAK-80 No. of tools used: 1 |

Total Machining Time: 31min. 43sec Workpiece Dimension: 50 x 50 x 50mm Material: NAK-80 No. of tools used: 2 |

Standrd Accessories

| 1. Full-closed splash guard | 2. Automatic power off |

| 3. Oil skimmer system | 4. Water gun and air gun |

| 5. MITSUBISHI controller M70A | 6. Chips flush coolant system |

| 7. Tools box | 8. Work lamp |

| 9. Arm type ATC with 24 tool capacity | 10. Automatic lubrication system |

| 11. Heat exchanger | 12. Alarm light |

| 13.Screw type chip conveyer | 14. Automatic tool length measuring device |

| 15.Spindle oil cooler system | 16.Spindle speed 10000rpm |

Optional Accessories

| 1.FANUC system controller | 2.SIEMENS system controller |

| 3.Direct type Spindle 12,000/15,000 RPM | 4.Built type Spindle 20,000/24,000 RPM |

| 5.Coolant through spindle | 6.Air conditioner |

| 7.Transformer | 8.Voltage regulator |

| 9.Flat type chip conveyer | 10.CE mark |

| 11.3-Axes optical scale | 12.Breakage detection system |

| 13.Oil mist collector | 14.Inverter ATC System |

Specification

| Model | MT-750 V | MT-750 VS | ||

| Table | Size | mm | 800×450 | 800×450 |

| T-slot (width x no x distance) | mm x T | 18x5x90 | 18x5x90 | |

| Maximun table load | kgs | 300 | 300 | |

| Travel | X, Y, Z -axis | mm | 700x500x500 | 700x500x500 |

| Table top surface to spindle nose | mm | 100-600 | 100-600 | |

| Distance between spindle center and column surface | mm | 580 | 580 | |

| Linear guideway type ( X / Y / Z-axis ) | mm | 30/35/35 | 30/35/35 (Roller type) | |

| Ball screw ( X / Y / Z-axis ) | mm | ∅32/∅32/∅32 | ∅32/∅32/∅32 | |

| Spindle | Spindle holder | BELT | DIRECT | |

| Taper | BT40 | BT40 | ||

| Diameter | mm | 70 | 70 | |

| Spindle speed | rpm | 10000 | 10000 | |

| Feed | Cutting feedrate X/ Y/ Z (G01) | m / min | 20/20/20 | 20/20/20 |

| Rapid feedrate X/ Y/ Z (G0) | m / min | 36/36/36 | 36/36/36 | |

| ATC | Type | ARM | ARM | |

| Max. tool Dia | mm | ∅75 /∅150 | ∅75 /∅150 | |

| Max. tool length | mm | 300 | 300 | |

| Max. tool weight | kgs | 7 | 7 | |

| Tool type | BT40 | BT40 | ||

| Tool magazine capacity | T | 24 | 24 | |

| Motors | Spindle motor (Cont./30 min) | kw | 7.5/11 | 7.5/11 |

| X/ Y/ Z -Axis | kw | 2.0/2.0/3.0 (Mitsubishi) 1.6/1.6/4.0(FANUC)) |

2.0/2.0/3.0 (Mitsubishi) 1.6/1.6/4.0(FANUC) |

|

| Coolant pump | kw | 0.75 | 0.75 | |

| Other | Machine Space ( L x W ) | mm | 2200×2050 | 2200×2050 |

| Coolant tank capacity | L | 250 | 250 | |

| Net weight | kgs | 4400 | 4400 | |

| * All specification , dimension and design characteristics shown in this catalogue are subject to change without notice. |